Ultimate Source for Advanced Vehicle Instrument Cluster Fixing Techniques

In the realm of contemporary car upkeep, the complexities of instrument collection repair work stand as a critical element of making certain the optimum functioning of a vehicle (tahoe instrument cluster repair). As modern technology advances, so do the complexities of these essential components, necessitating an extensive understanding of innovative repair work strategies. With a myriad of potential concerns that can occur within tool clusters, having a trustworthy source that uses comprehensive advice on troubleshooting and fixing these obstacles ends up being vital. By checking out the tools required, common troubles ran into, and detailed repair approaches, one can outfit themselves with the knowledge needed to browse the elaborate world of auto tool cluster repair with confidence and accuracy.

Importance of Advanced Instrument Cluster Repair Work

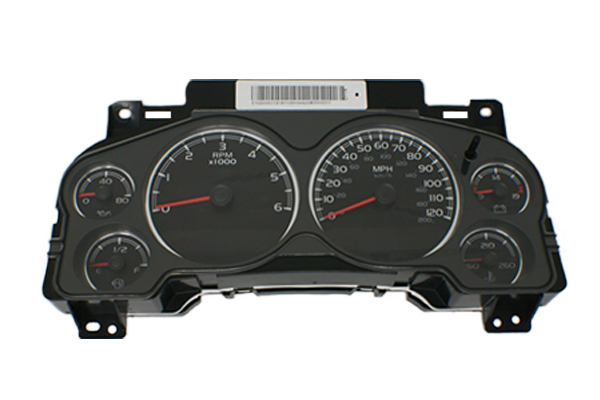

Comprehending the value of sophisticated tool cluster repair service is necessary for maintaining the capability and accuracy of contemporary vehicle systems. The instrument collection works as the hub of details for motorists, showing important data such as speed, gas degrees, engine temperature, and alerting indications. With the development of modern technology, instrument clusters have advanced to incorporate complicated electronic screens and digital components, making repair work more elaborate and specialized.

Appropriate fixing and upkeep of the instrument cluster are vital for ensuring the security and performance of the car. Problems with the tool collection can bring about unreliable analyses, breakdowns in crucial systems, and safety threats on the roadway. Advanced tool collection repair methods include identifying digital mistakes, altering sensors, and reprogramming software application to recover optimum efficiency.

Devices and Tools Required

To efficiently resolve the elaborate repair demands of modern vehicle tool clusters, a specialized set of tools and tools is important. Some of the key tools required for innovative auto tool collection repair work consist of precision screwdrivers, trim elimination tools, soldering devices, electronic multimeters, and diagnostic scanners. By having actually these specialized devices and equipment on hand, professionals can efficiently diagnose and resolve complex issues in auto tool collections.

Common Problems and Solutions

Several common issues often run into in auto instrument clusters can be efficiently solved via targeted services. One prevalent issue is faulty determines, which may arise from a malfunctioning stepper electric motor. To address this, replacing the stepper motor can restore precise gauge readings. Another common problem is dark or flickering lights on the tool cluster (tahoe instrument cluster repair). This can usually be connected to a defective bulb or poor connections. By changing the light bulb or ensuring protected connections, the lighting problem can be quickly treated. In addition, a malfunctioning odometer or display screen is a regular concern. This could be because of a faulty display screen system that needs to be changed to recover proper functionality. Recurring power or full failure of the tool collection may stem from a blown fuse or circuitry concern. Checking and changing the fuse, as well as evaluating the circuitry for any type of damages, can aid settle these power-related issues successfully. By determining these usual problems and applying the appropriate remedies, vehicle instrument collection performance can be recovered efficiently.

Step-by-Step Fixing Overview

A systematic method to identifying and fixing car instrument collection problems is essential for attaining effective and accurate results. To start the repair process, the primary step is to carefully examine the tool collection for any visible damages such as burnt-out light bulbs, broken screens, or loose connections. Next, it is crucial to carry out a diagnostic scan utilizing customized tools to identify any type of underlying digital problems. As soon as the trouble locations are identified, the fixing can commence by click site either changing damaged elements, fixing damaged wiring, or altering sensing units.

Tips for Preventative Upkeep

After performing a comprehensive analysis check and finishing required repair services on the auto instrument collection, executing regular preventative maintenance steps is vital to ensure long-term functionality and ideal performance of the automobile's vital assesses and indicators. To begin, it is important to routinely inspect the tool cluster for any signs of wear, such as fading display screens this link or malfunctioning lights. Maintaining the collection tidy from dirt and particles can additionally protect against damages to fragile parts. In addition, inspecting the links and circuitry for any indications of deterioration or loose links can help protect against electric concerns that may impact the collection's efficiency.

In addition, updating the software application of the tool cluster when essential can make sure compatibility with any new functions or systems in the vehicle. It is likewise recommended to adhere to the maker's recommended upkeep routine and guidelines for the instrument cluster to maintain its long life. By including these preventative upkeep tips right into your routine vehicle treatment, you can help expand the lifespan and integrity of your auto tool cluster.

Conclusion

In conclusion, innovative vehicle instrument collection fixing methods are necessary for keeping the functionality of contemporary cars. By using the proper devices and equipment, attending to typical problems, and adhering to a click here to find out more detailed repair service guide, service technicians can efficiently repair and identify tool collection problems. Implementing preventative upkeep methods can assist lengthen the lifespan of the instrument cluster and protect against future issues from occurring.

By checking out the devices called for, usual problems ran into, and detailed repair approaches, one can equip themselves with the knowledge needed to navigate the intricate globe of auto tool collection fixing with self-confidence and accuracy.

An organized strategy to diagnosing and fixing vehicle tool collection concerns is vital for accomplishing precise and effective outcomes. By following this detailed guide carefully, auto service technicians can successfully repair and detect tool collection concerns with accuracy and confidence.

In conclusion, sophisticated automobile tool cluster repair techniques are necessary for preserving the performance of modern vehicles. By utilizing the appropriate tools and equipment, addressing usual problems, and following a detailed repair guide, technicians can effectively fix and detect tool collection problems.

Comments on “Top-Notch Tahoe Instrument Cluster Repair: Dealing With Gauge Issues Made Easy”